In the modern industrial landscape, efficient water management systems are fundamental for both residential and commercial infrastructures. As global demand for reliable plumbing and water distribution systems increases, the role of brass ball water valve factories has become more prominent. These factories specialize in producing high-quality brass ball water valves, which are critical components for regulating water flow in homes, industries, and municipal water systems. The precision, durability, and efficiency of brass ball valves make them a preferred choice across various sectors, and the factories that produce them are driving innovations to meet rising global demands.

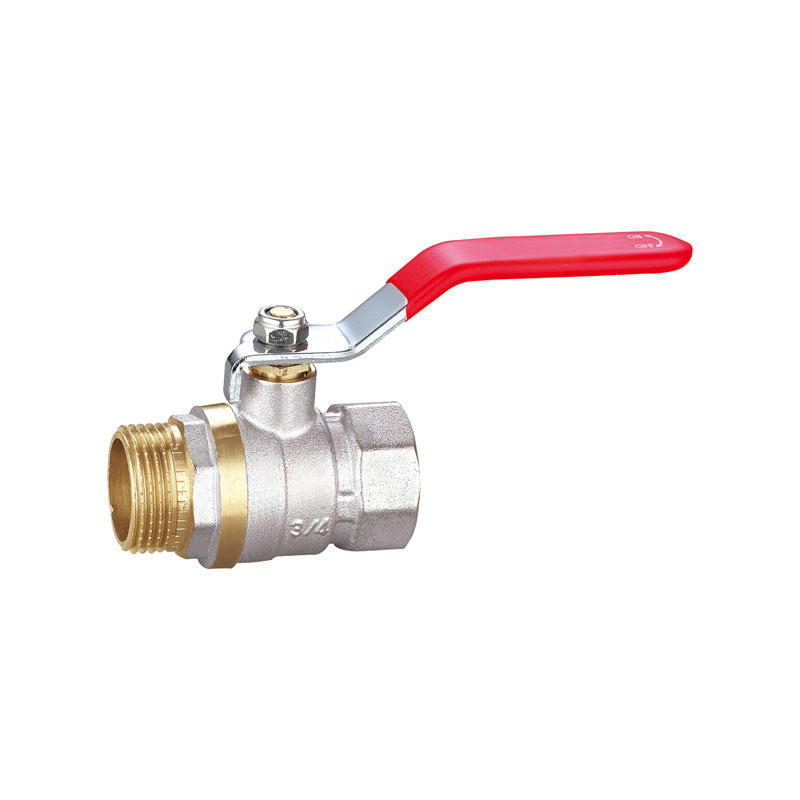

A brass ball water valve is a type of shutoff valve that uses a rotary ball with a hole through it to control water flow. The brass ball rotates within the valve, allowing or blocking water depending on its position. The material choice—brass—is particularly advantageous for water systems because of its corrosion resistance, durability, and suitability for both high and low-temperature environments. Brass ball water valves are often used in plumbing, industrial pipelines, and irrigation systems due to their ability to withstand conditions while providing reliable performance.

Brass ball water valve factories are responsible for the precision manufacturing of these valves, ensuring they meet strict industry standards. These factories utilize advanced manufacturing techniques, including CNC machining, forging, and casting, to produce valves that are both robust and reliable for long-term use in various water systems.

Water management is critical in many industries, and brass ball water valve factories play a vital role in ensuring efficient water flow regulation. One of the primary applications of brass ball valves is in residential plumbing systems, where they provide homeowners with easy control over water supply. The precision manufacturing processes used in brass ball water valve factories ensure that the valves offer smooth operation, minimizing the risk of leaks or malfunctions.

Beyond residential use, brass ball valves are extensively employed in industrial water systems. In factories, refineries, and chemical plants, the precise control of water flow is essential for production processes. Brass ball water valve factories provide customized solutions to meet the specific needs of different industries, producing valves that can handle various pressures and flow rates. By supplying high-quality valves, these factories contribute to the overall efficiency and safety of industrial water management systems.

Municipal water distribution systems also rely heavily on brass ball water valves to regulate water flow across cities and towns. In these large-scale systems, reliability and durability are crucial to preventing water loss and maintaining a consistent supply. Brass ball water valve factories ensure that their products meet the high standards required for public water systems, where even minor valve failures can have significant consequences.

The brass ball water valve industry has seen significant technological advancements in recent years. Automation and computer-aided design (CAD) systems have streamlined the manufacturing process, allowing brass ball water valve factories to produce valves with greater precision and efficiency. CNC machining, in particular, has revolutionized valve production by enabling the creation of intricate valve components with tight tolerances, which ensures a seal and performance in water systems.

Additionally, brass ball water valve factories have embraced sustainable practices in their production processes. Many factories are adopting environmentally friendly methods such as reducing energy consumption, recycling materials, and minimizing waste. These initiatives not only reduce the environmental impact of valve production but also align with the growing demand for sustainable products across industries.

Another key area of innovation in brass ball water valve factories is the development of valves with enhanced durability and performance. By utilizing advanced alloys and surface coatings, these factories are creating valves that offer improved resistance to corrosion, wear, and temperatures. These innovations extend the lifespan of brass ball water valves, reducing the need for frequent replacements and lowering maintenance costs for end-users.

languages

languages

English

English русский

русский