In industrial applications, controlling the flow of liquids and gases is essential for safety, efficiency, and functionality. Brass ball valves have emerged as one of the reliable and versatile tools in fluid control systems. Known for their durability, corrosion resistance, and ease of operation, brass ball valves are a staple in industries ranging from plumbing and manufacturing to oil and gas. These valves provide an solution for both residential and industrial fluid handling systems, ensuring precise flow regulation under demanding conditions.

What is a Brass Ball Valve?

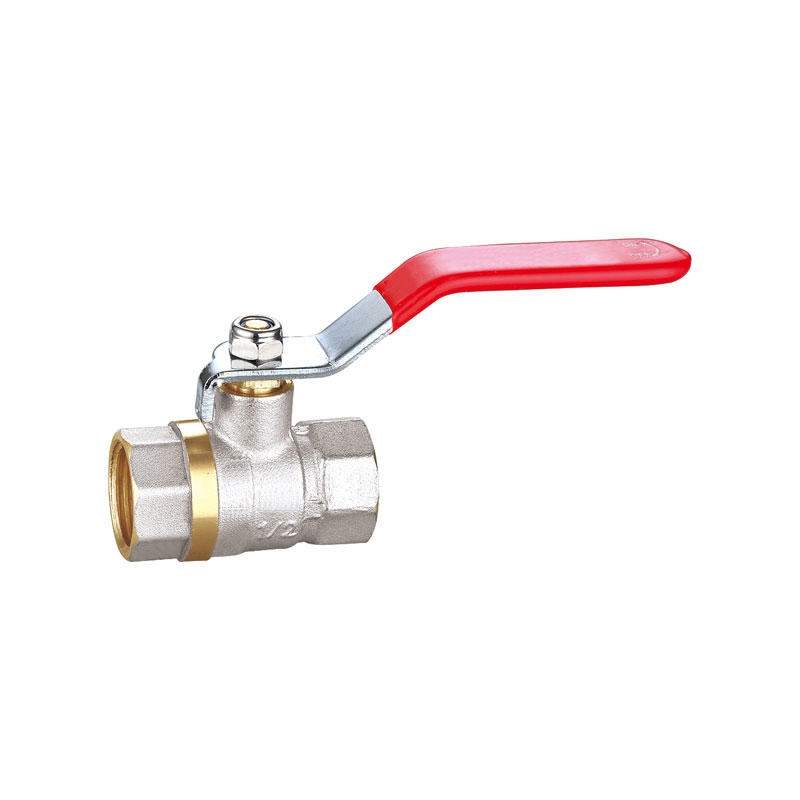

A brass ball valve is a type of valve that uses a ball with a hole through the middle (called a "ball") to control the flow of fluids. The ball sits inside the valve body, and as it rotates, it either blocks or allows fluid to pass through the valve. When the ball is rotated 90 degrees, it either opens or closes the valve, enabling the user to control the flow of water, gas, oil, or other fluids with ease. Brass, an alloy of copper and zinc, is commonly used for these valves because of its strength, corrosion resistance, and long lifespan.

Brass ball valves are widely used because they offer an easy-to-operate, durable solution for controlling fluid flow. They are suitable for applications involving water, steam, and air, as well as many other gases and liquids. Their simple, robust design ensures they can withstand high pressures and temperatures, making them suitable for a broad spectrum of environments.

Applications of Brass Ball Valves

The versatility of brass ball valves makes them an essential component in a wide range of industries. In plumbing systems, brass ball valves are commonly used to control the flow of water in residential and commercial applications. For example, they are installed at the water main or at individual fixtures to allow for easy shut-off during maintenance or repairs.

In industrial sectors, brass ball valves are crucial in applications requiring reliable flow control under high-pressure conditions. For example, in the oil and gas industry, these valves are used to regulate the flow of crude oil, natural gas, or other petrochemical products. The ability to operate efficiently under pressure and corrosive environments makes brass ball valves a preferred choice for many professionals in this industry.

In HVAC systems, brass ball valves are used to regulate the flow of refrigerants or water used in heating and cooling processes. Their ability to handle high flow rates while maintaining precise control makes them ideal for regulating temperature control systems, which often require high reliability and safety standards.

The Advantages of Brass Ball Valves

One of the main reasons brass ball valves are so widely used is their ability to offer quick and efficient flow control. When the valve handle is turned 90 degrees, the ball inside the valve opens or closes the flow path alinstantly, providing immediate control. This feature is especially valuable in emergency situations, where rapid shutdown or activation of fluid flow is essential for safety.

Another key advantage of brass ball valves is their durability. Brass is an incredibly strong material that can withstand high pressures and temperatures without degrading. This makes brass ball valves an ideal choice for applications where valves are exposed to harsh operating conditions, such as in chemical processing plants, oil rigs, or manufacturing plants.

Brass is also resistant to corrosion, making it an material for fluid handling systems that may involve exposure to water, chemicals, or high humidity environments. Unlike other materials, brass will not rust or corrode easily, ensuring that the valves continue to function effectively for extended periods of time without the need for frequent replacement.

In addition to their durability, brass ball valves require minimal maintenance. The design of these valves allows for easy disassembly and cleaning, which makes them easy to repair or replace when necessary. Unlike other valve types that can become clogged or corroded over time, brass ball valves maintain their function with minimal wear and tear.

Brass Ball Valves in Sustainable Systems

As industries across the globe continue to focus on sustainability and energy efficiency, brass ball valves are playing an important role in helping to reduce water and energy waste. Because of their ability to quickly shut off or regulate fluid flow, these valves help minimize water or chemical losses, to more efficient systems.

languages

languages

English

English русский

русский